Servo Energy Save Plastic Injection Machine

- Desctription

- Features

-

Video

Servo energy-saving injection molding machine: there is no extra energy consumption due to output volume changes according to load alteration. In the phase of holding pressure, servo motor lowers rotate speed and consumes a little of energy. In the phase of cooling, motor doesn’t work and consumes no energy. According to different products, servo energy-saving injection molding machines will save 20%-80% energy and bring you prominent economic benefit.

SUPER ENERGY SAVING

Compared with variable pump system, it can save 40% of the power, compared with constant flow pump and speed setter. It can save 60% of the power (the different kinds of products has different energy saving effects).

HIGH PRECISION HIGH PRESPONSE

The pressure sensor and rotary encoder with high precision and high sensitivity achieve pressure, flow closed-loop control, allows the repeat precision error to be less than 1%. When servo motor reaches big quantity, the output power just needs 0.05 seconds.

LOW NOISE

The noice is below 78db, servo motor has almost no noise during no operation.

SAVE THE COOLING WATER

No constant flow pump and speed set motor overflow heating, when the temperature of hydraulic oil is lower, the cooling water is reduced greatly.

JTZ-HS Series Double Color Injection Machine

- Desctription

- Features

-

Application

Mix double color injection machine is newly designed for producing color product such as tooth brush, bomb, shoe upper etc. This machine adopt double servo motor system, two injection can work separately and same time. Special controller is equipped on this machine to provide different injection function as per different product.

Mixed two-color injection molding machine is the latest research and development of our company to produce mixed two-color product injection molding machine, can be used to produce two-color toothbrush, comb, shoe upper belt and other daily two-color products.

The machine adopts double servo energy-saving system, the main and auxiliary screw can realize alternately or simultaneously injection function;

Equipped with dual color machine control computer, for different products to provide a variety of injection functions.

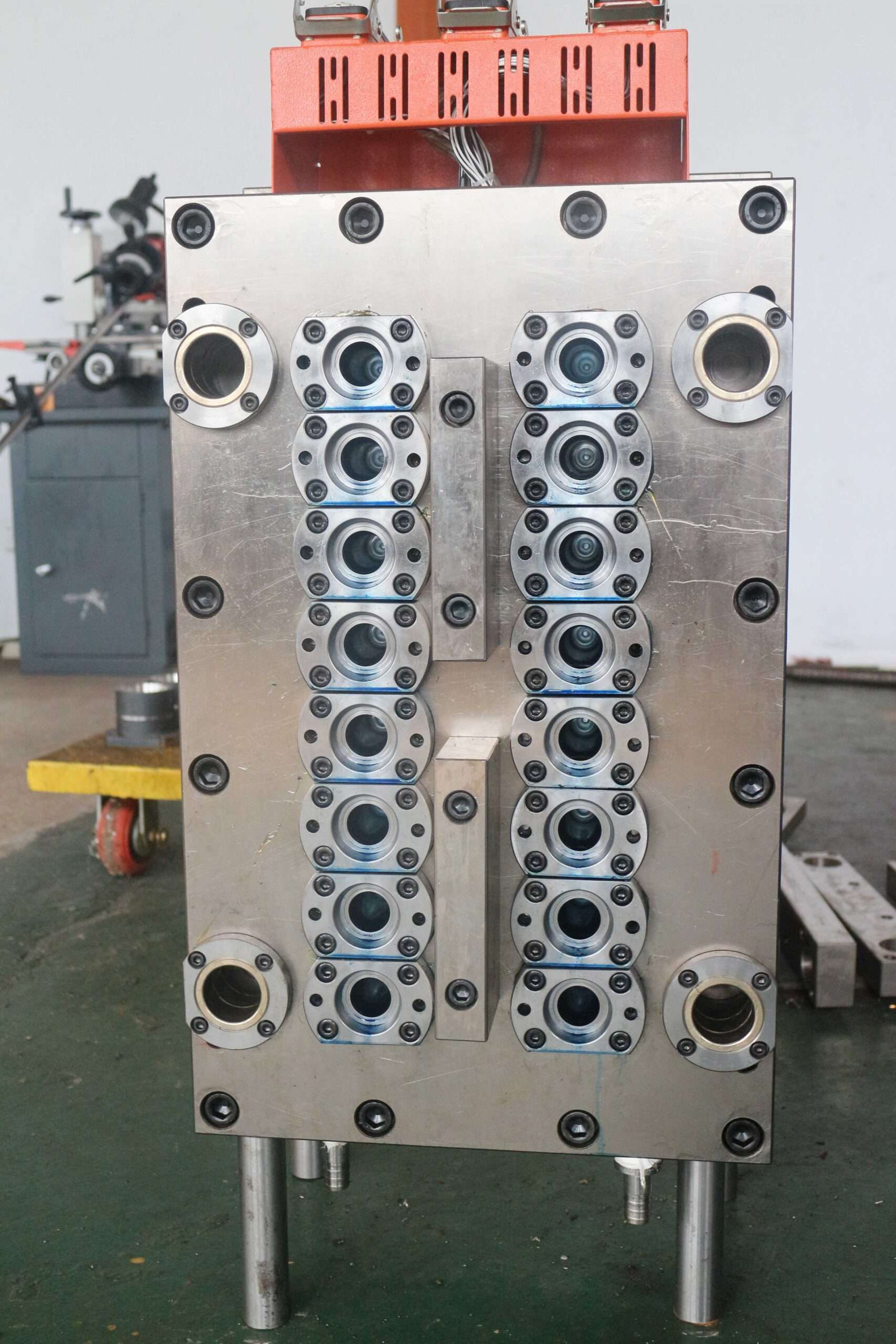

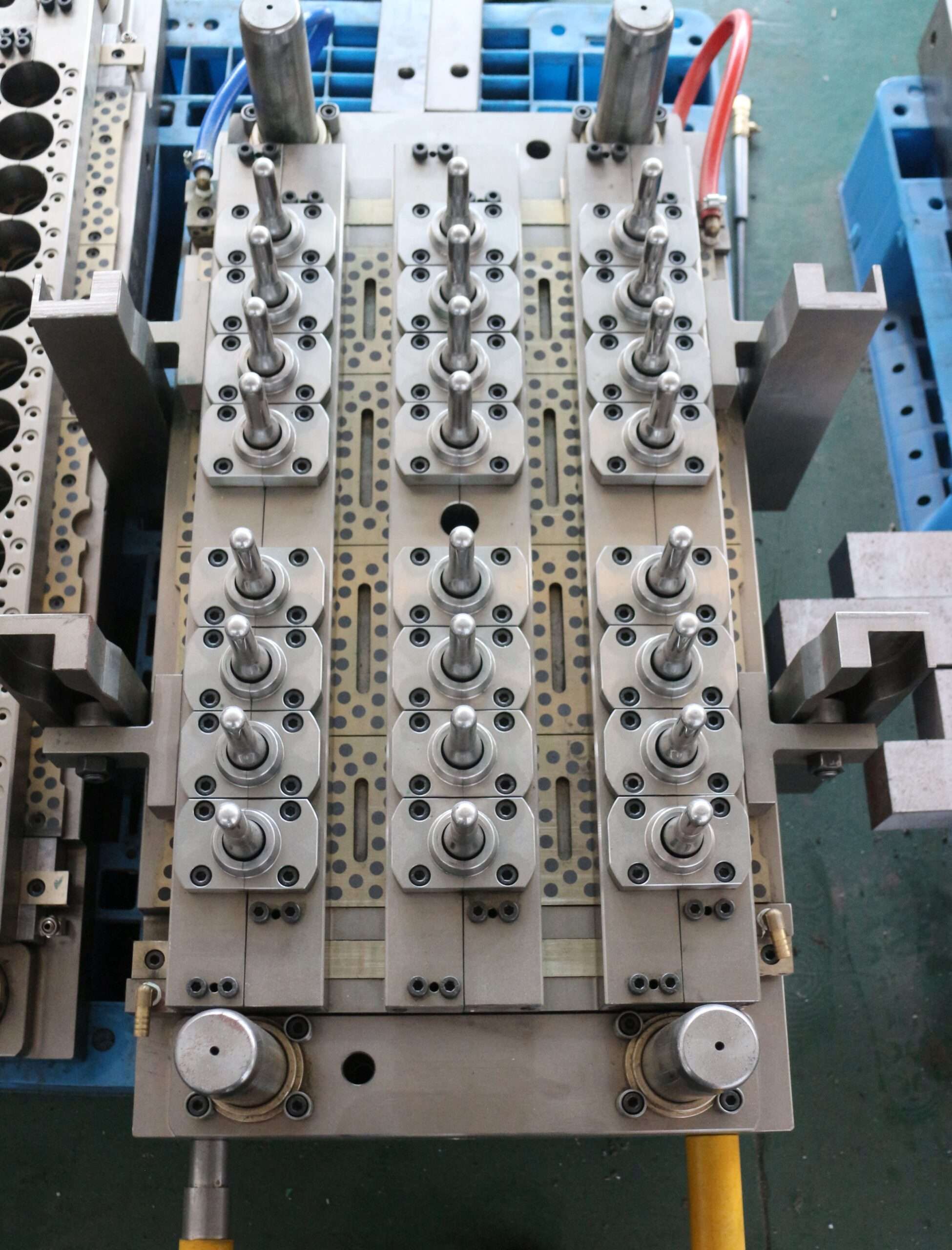

JTZ Series Standard PET Preform Injection Machine

- Desctription

- Application

-

Video

JTZ standard PET injection moulding machine is modified on the basis of regular machine to be suitable for product different kinds of preform.

- Adopt special design for PET material, long L/D to increase the efficiency of charging and shot weight.

- Increased ejector force and stroke to improve the ejecting speed.

- Servo energy saving system could be chosen for machine, electricity consumption will be reduced 30% to 50%.

- We can provide full set equipment for PET bottle such as injection machine, blow moulding machine, mould and other accessories.

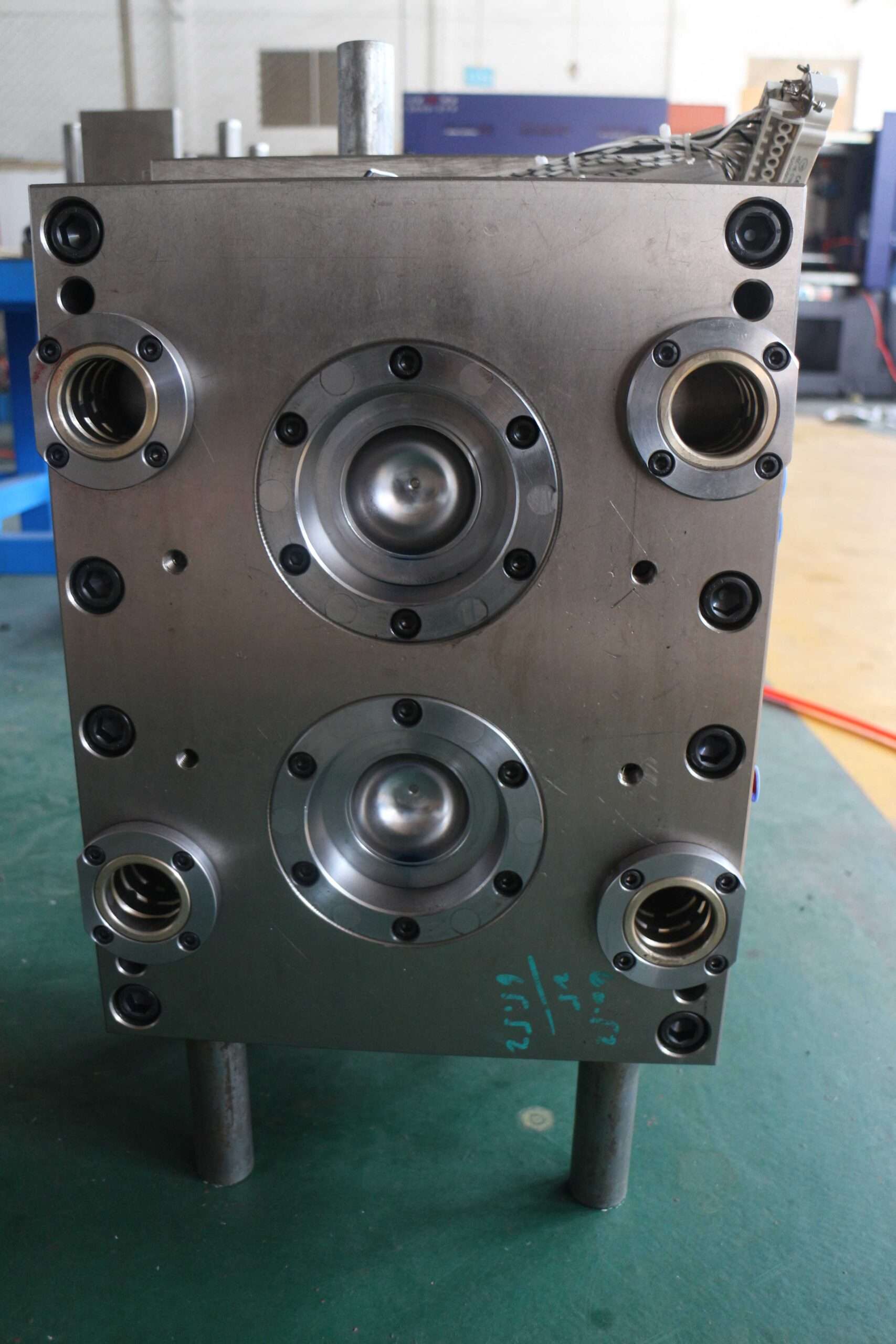

Servo Energy Save Plastic Injection Machine

- Desctription

- Application

-

Video

Small clamping unit with large shot weight, suitable for different.

- Equip with low speed and high torque hydraulic motor which is good for charging material stably and fast.

- Big diameter screw and barrel, special design for PET material.

- Increased ejector force and stroke to improve the ejecting speed.

- Equip with special cooling water distributor and compressed air valve for easy operation.

- Max mould height is big for different type preform mould.

- Platen hole could be drilled specially according to preform mould, cancel clamp plate for fixing mould.

- Equipped with socket for preform conveyor.

About Us

Taizhou Huangyan Gunther Mould Co., Ltd. is a professional preform mould, injection machine production and export enterprises, the company was founded in 2002 ,Our company is specialized in the production and processing of preform molds, and has many years of experience in producing preform molds for beverage bottles, mineral water bottles, oil bottles, cosmetic bottles and other types of bottles. we have consistently uphold: “customer first, service first, genuine” business philosophy, always uphold the integrity, innovation, development-oriented principle.

Taizhou Huangyan Gunther Mould Co., Ltd. sales to United States, Europe, Australia,Vietnamese, Thailand, Singapore, Brazil, Africa and other countries, and we sincerely hope to establish friendly business relations with customers from all over the world.

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business

Relationships with new clients around the world in the near future.

Why Choose Us

quality and affordable prices are what we are here to do for our clients.

delivery on time is our number one topmost priority.

we ensure our clients are satisfied and happy with our mould for them.

What Client Say About Us